The Businova H2, the first French hydrogen bus

As a substitute for thermal vehicles, electric mobility is set to play an increasing role in the fight against climate change and air pollution, due to the total absence of CO2 and particle emissions during its use. There are two electric vehicle technologies: battery-powered vehicles and hydrogen-powered vehicles. The hydrogen-powered electric bus solution meets zero emission requirements without adding operational constraints for operators. With the acceleration for cities to switch their transport fleet to zero emission vehicles, the hydrogen powered bus appears as an ideal solution.

This long-proven technology has the ability to adapt to all weather conditions, unlike pure electric buses, which see their performance drop by 20 to 30% in these conditions. Similarly, a hydrogen bus is as efficient as a diesel bus in terms of capacity, acceleration and availability.

Finally, it can travel up to 300km per day, with performances similar to those of a diesel vehicle and a minimal recharging time, since a full tank takes only 20 minutes.

No safety issue either, a hydrogen bus is comparable to CNG in this respect.

Contrary to natural gas, hydrogen is much lighter than air and can therefore diffuse quickly, which is a very favourable factor for its safety.

Hydrogen vehicles can run on “green” or “decarbonized” hydrogen, in particular when it is produced by electrolysis of water, from renewable energies. It is in this case that we discover the relevance of this motorization.

As early as 2010, when the Businova project was launched, SAFRA was very interested in hydrogen technology, which makes it possible to maintain a reduced battery capacity by providing additional energy.

This is why, as soon as the specifications for the Businova were drawn up, SAFRA worked on a concept for an evolving vehicle, allowing for the easy development of different engines, but also for the evolution of its engine towards a new technology. This is thanks to a unique architecture: a very ingenious bi-modular chassis and a self-supporting structure that provide flexibility and an almost unlimited capacity for adaptation.

Thus, from the design stage to the approval process, the Businova’s development is geared towards scalability. It is designed as an assembly of interchangeable “bricks”. This technical innovation provides great flexibility for the integration of new components, as well as the ability to easily upgrade the vehicle to new and different energy solutions.

Thus, in 2017, SAFRA Constructeur launched the development of the hydrogen Businova for marketing in 2018, with the first 6 sales for the Artois-Gohelle agglomeration, then BE Green with 5 vehicles and finally Le Mans, which started with its first hydrogen bus.

In practice, this version retains all of the vehicle’s original architecture, with a hydrogen range extender. The 250 kW electric drive train is powered by a 132 kWh lithium-ion battery pack. The fuel cell is supplied by Michelin and the system integrates a 30.6 kg hydrogen storage at 350 bars, which allows a range of over 300 km per day. Michelin’s hydrogen module is built around a 30 kW fuel cell.

In addition, the hydrogen solution proposed by SAFRA presents an original architecture compared to the electric H2 buses that have already been marketed and tested worldwide in recent years. Most of these electric H2 buses have been designed according to a so-called “full-power” architecture. This type of architecture requires relatively high fuel cell power, which can range from 150 to 250 kW on some types of buses. On the contrary, thanks to its bi-modular chassis and its drive train, the Businova H2 concept is based on the development of an innovative “mid-power” architecture based on an intelligent hybridization between a 30 kW fuel cell and a 132 kW battery pack. Compared to other existing electric H2 bus solutions, the amount of hydrogen required to ensure a range of more than 250 km is consequently lower: only 30 kg of hydrogen distributed in 30 minutes will be necessary to refuel Businova, compared to 45 to 50 kg with competing H2 bus architectures. Thanks to all these advantages, the operation of a Businova H2 bus can be carried out using medium capacity hydrogen filling stations (less than 80 kg/day), thus greatly limiting the investment and operating costs of H2 infrastructures (production and distribution) usually required with “full-power” fuel cell solutions.

The Syndicat Mixte des Transports Artois-Gohelle (SMTAG) has placed its trust in SAFRA Constructeur in its ambitious project to reorganize its network towards alternative energies such as hydrogen. Six hydrogen buses were ordered from SAFRA under a public contract in 2018 and will be the first to be put into operation in France. The Artois-Gohelle conurbation is a very vast and extensive territory, which includes 44% of the population of the Pas-de-Calais, encompassing 150 municipalities, making it the 6th largest transport area in France.

It is within the framework of a clear and committed environmental policy in favor of sustainable mobility that the SMT AG has chosen hydrogen technology. The SMT AG has awarded the refueling of the 6 hydrogen buses to ENGIE, which benefits from a large experience and expertise for almost 20 years now, through its subsidiary GNVERT.

The hydrogen production station will be installed on the new dedicated site in Houdain, which will also serve as a depot. SMT AG has chosen electrolysis for the production of hydrogen. The company Mc Phy, a national player, was selected for the production and distribution of hydrogen, thanks to a McLyzer electrolyzer that will produce clean hydrogen on site to supply a high-capacity hydrogen statioń with a high service rate.

By opting for hydrogen mobility, SMT AG is reconciling the comfort of its users, continuitý of service, and participation in the reduction of air pollution and the improvement of public health.

Businova CAP supplier

The Michelin Group is committed to improving the mobility of its customers in the long term. As a leader in the tire industry, Michelin designs, manufactures and distributes the tires best suited to their needs, as well as services and solutions to improve mobility efficiency. Michelin also offers digital services, maps and guides that provide customers with unique experiences during their travels and journeys. Michelin also designs high-tech materials for the mobility industry.

Headquartered in Clermont-Ferrand, Michelin is present in 170 countries, employs 111,700 people and operates 68 plants in 17 countries that together produced 187 million tires in 2016.

www.michelin.com

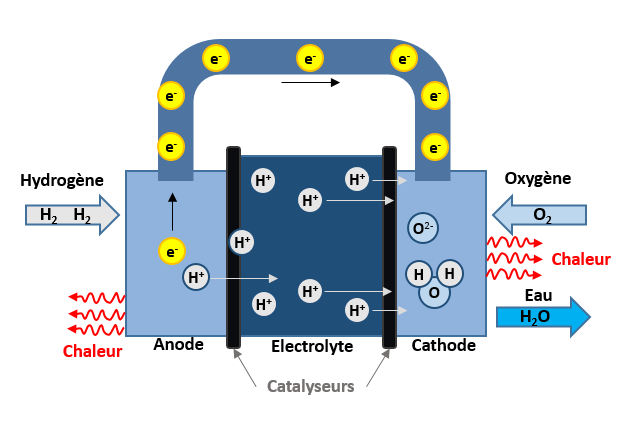

The principle of the fuel cell is to produce electricity from hydrogen, associated with oxygen (O2). The particularity of the production of energy from a fuel cell is that there is no polluting discharge, only water is generated by this process. In addition, since the fuel cell produces heat, it can be used to heat the vehicle’s interior. This is the case in the Businova H2’s heating system, which uses all the heat produced by the fuel cell, thus reducing the energy consumption of the batteries to heat the vehicle. As a result, the fuel cell system is an excellent energy source for use in transportation that corresponds in every way to the changes linked to the current ecological transition.

On the Businova H2, the hydrogen module is built around a fuel cell supplied by MICHELIN, with a capacity of 30 kW. Michelin’s fuel cell technology can cover a range of applications from 5 to 100 kW. MICHELIN’s teams have worked hard to ensure that the fuel cell is lightweight and very compact, making it easy to integrate into the vehicle.

In a world facing ever more pressing environmental issues, transition

“A stone has no hope of being anything other than

The fourth leading cause of mortality in the world, air